Borrow from Six Sigma principles and conduct a fact-finding mission, evaluating where your team is already successful, what’s working well, and what type of environment drives those ideal results. Use the information you’ve gathered as a guide to investigate which project management methodology works for your specific goals, constraints, and timelines. In the measure stage of DMAIC Six Sigma, you will often get ready to sort your data using visualization tools like CTQ or critical to quality tree charts.

Control charts

Adding value and ensuring the quality of value is by far one of the most important components when attempting to differentiate yourself from the competition and get a step ahead. It may also be utilized to optimize supply chain processes and increase customer satisfaction. The benefits of utilizing Six Sigma will go beyond simple-problem solving and considering the entire production process from raw materials to the end product as opposed to only the end product.

Advantages & Disadvantages of Six Sigma methodology

These steps aren’t meant so much as to replace the 5 stages mentioned above, but to offer a secondary perspective which can function alongside one another, or be superimposed onto each other. As before, here is where you identify problems like bottlenecks or wasted resources. Right from this very first stage you should have clear goals in mind, and ones that never fail to consider the end user or customer.

Top 10 Factors for Project Success

Though there are several Six Sigma in Manufacturing | Advantages & Disadvantages. The drawbacks here are mainly based on increased costs due to increased quality. With the six sigma implementation, the manufacturing industry has foreseen several benefits rather than these drawbacks. Six Sigma is a data-driven methodology that seeks to eliminate defects, enhance processes, and ultimately improve the quality of outputs through a disciplined and systematic approach. The primary goal of Six Sigma is to reduce defects to an incredibly low level (3.4 defects per million opportunities) and thus enhance customer satisfaction.

Best CRM for Small Business (November 2024 Update)

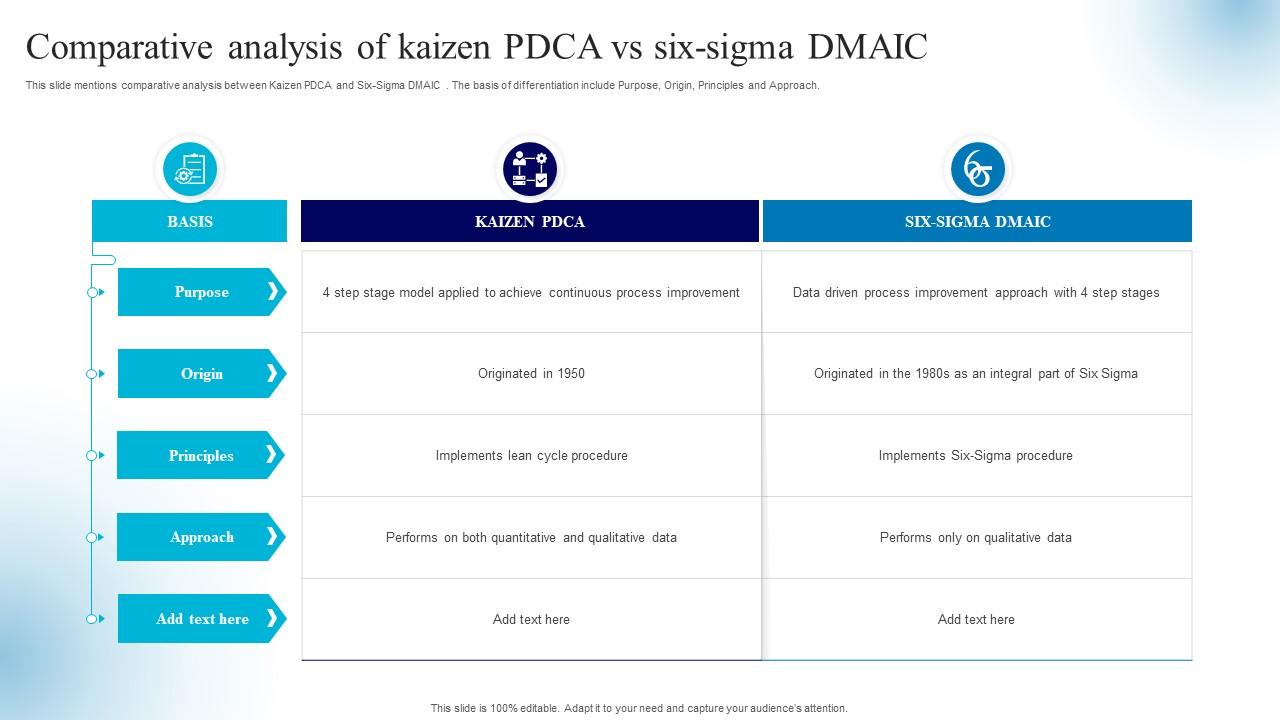

Lean Six Sigma is close to the Kaizen method, and uses tools like value stream mapping. We trust this Six Sigma summary has been satisfactory, thorough, entertaining and illuminating. We’ve taken you through the early days of good ol’ Bill Smith over at Motorola, went into statistical analysis and standard deviations, to eventually sum up the pros and cons to Six Sigma overall.

- In this way, teams can examine all possible causes and focus on those with the most significant impact.

- The high standard products have a good market, improving the business’s revenue generation.

- They both can improve quality and efficiency by controlling costs, eliminating waste, and creating flow in the production process.

As you start a new company or new enterprise, Six Sigma should come before Lean. Six Sigma delivers the best possible product to the customer with minimum variation. Implementing Lean will ensure maximum efficiency, but it may deliver an unusable product in the short-term. Lean and Six Sigma both had their starts in a complex manufacturing environment. As more and more businesses have adopted these tools, however, the objectives and goals of Lean and Six Sigma have begun to diverge. Six Sigma regards waste as a result of variation within a process, whereas Lean defines it as a process or activity that has no benefit to the customer.

There are many tools and methods available to apply six sigma into a business. As Six Sigma introduces significant modifications to existing processes, it’s natural for employees, especially veterans, to resist. This resistance isn’t just about nostalgia or stubbornness; it’s about fear of the unknown, concerns about adaptability, and worries about potential redundancies. This friction, if not managed correctly, can lead to decreased morale, lack of faith in the system, and even active pushback against Six Sigma initiatives.

APS is also compatible with various ERP, MRP, and MPS software around the globe. APS is essential for manufacturers that are seeking to maintain a competitive advantage and get ahead within their industry. And as a methodology, it can be implemented independently of whatever project management CRM you use.

Employees must obtain training from certified Six Sigma institutes in order for an enterprise to receive Six Sigma certification. Even if a firm wishes to implement Six Sigma without formal certification, turbotax live 2020 much training is necessary in order to understand the system and how to apply it to particular business processes. Many small businesses cannot possibly afford such training, even for a single employee.